ARTISAN

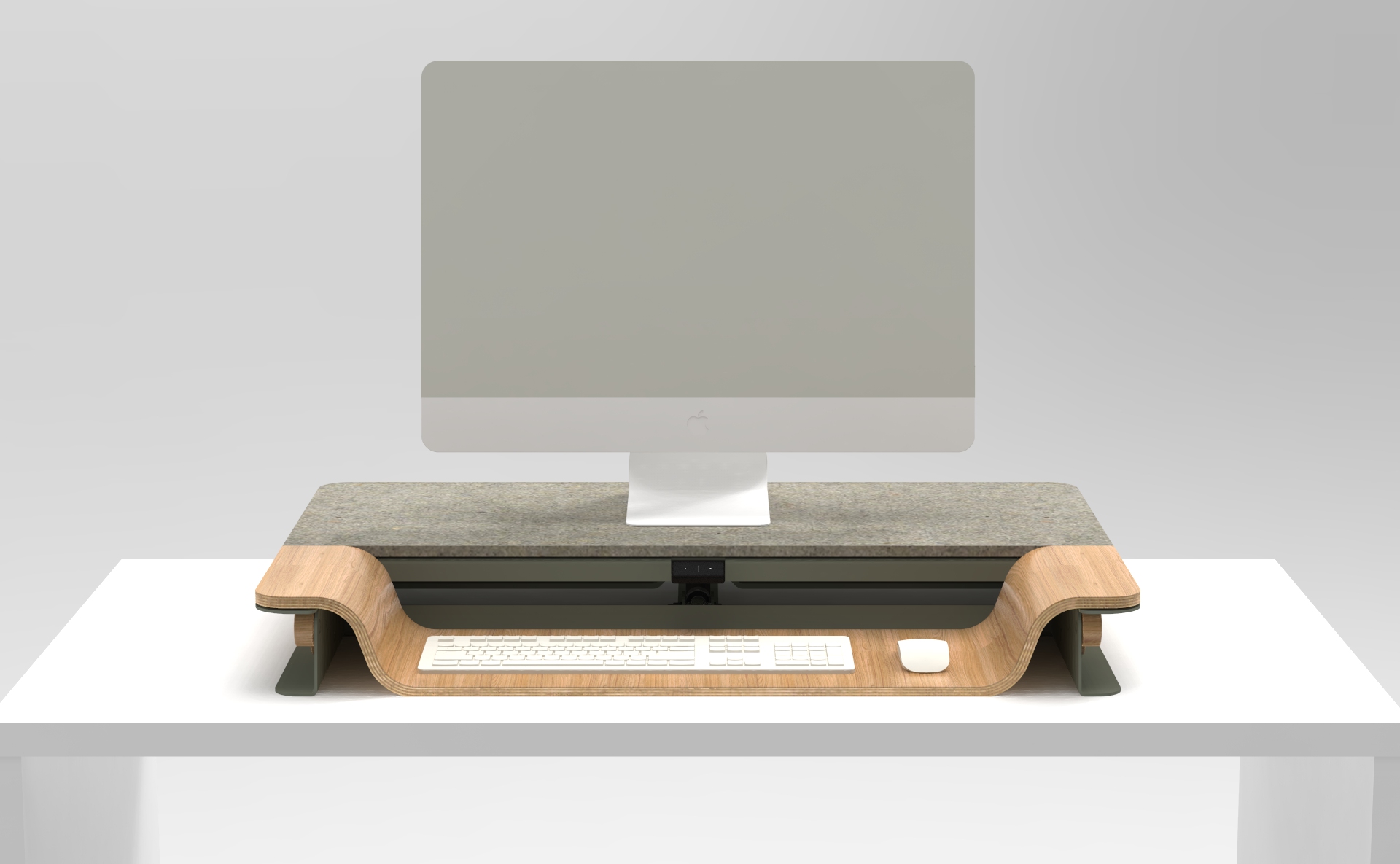

Some design worked alongside Studio Wood and with UK startup Artisan Office to create a desk riser that functions as beautifully as it looks. Standing while working is quickly being adopted by many desktop and laptop users, but most desk adaptors on the market offer utilitarian solutions that compromise aesthetics for function or cost.

We worked to create a desk riser that fits in with the home or contemporary working environment with innovative motion components without compromising the functionality.

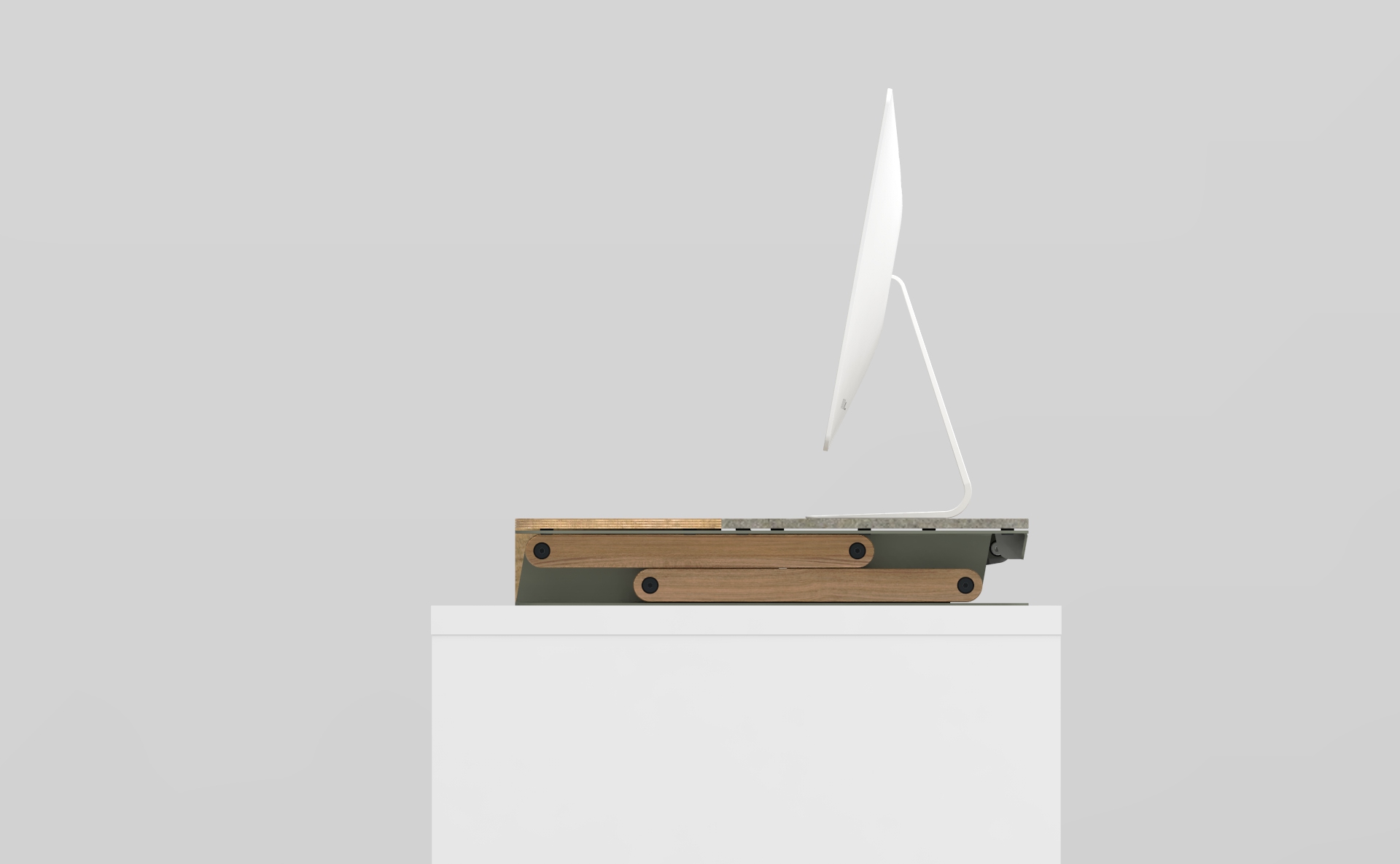

The Base plate is made of two welded folded sheetmetal. It has been studied and analysed to avoid any excess material, keep the aesthetic as sleak as possible and still comply with the stress applied when lifting the top plate and its load.

The top plate is also a two folded sheet metal welded assembly. It includes gussets to reinforce the structure and absorb the stress. All thicknesses are identical to keep the cost down.

The front feature is made of folded

plywood created through vacuum pressing. It has a total thickness of 12mm and is mounted to the top plate with some wood inserts keeping the top surface free from components.

The Birch wooden arms are laser cut and machined.

The motion is given by an electrical linear actuator with the motor positioned in line.

The tactile control switch commands the adaptor for up / down.

DrAFTING

Each components are defined on a manufacturing drawing providing the different suppliers with dimensional information as well as dimensional and geometrical tolerances, materials and finishes.

STress analysis

The base plate was the most tricky part to define as facing most of the stress. FEA helped finding the points to reinforced.

It revealed to be fairly close to what really happen physically.

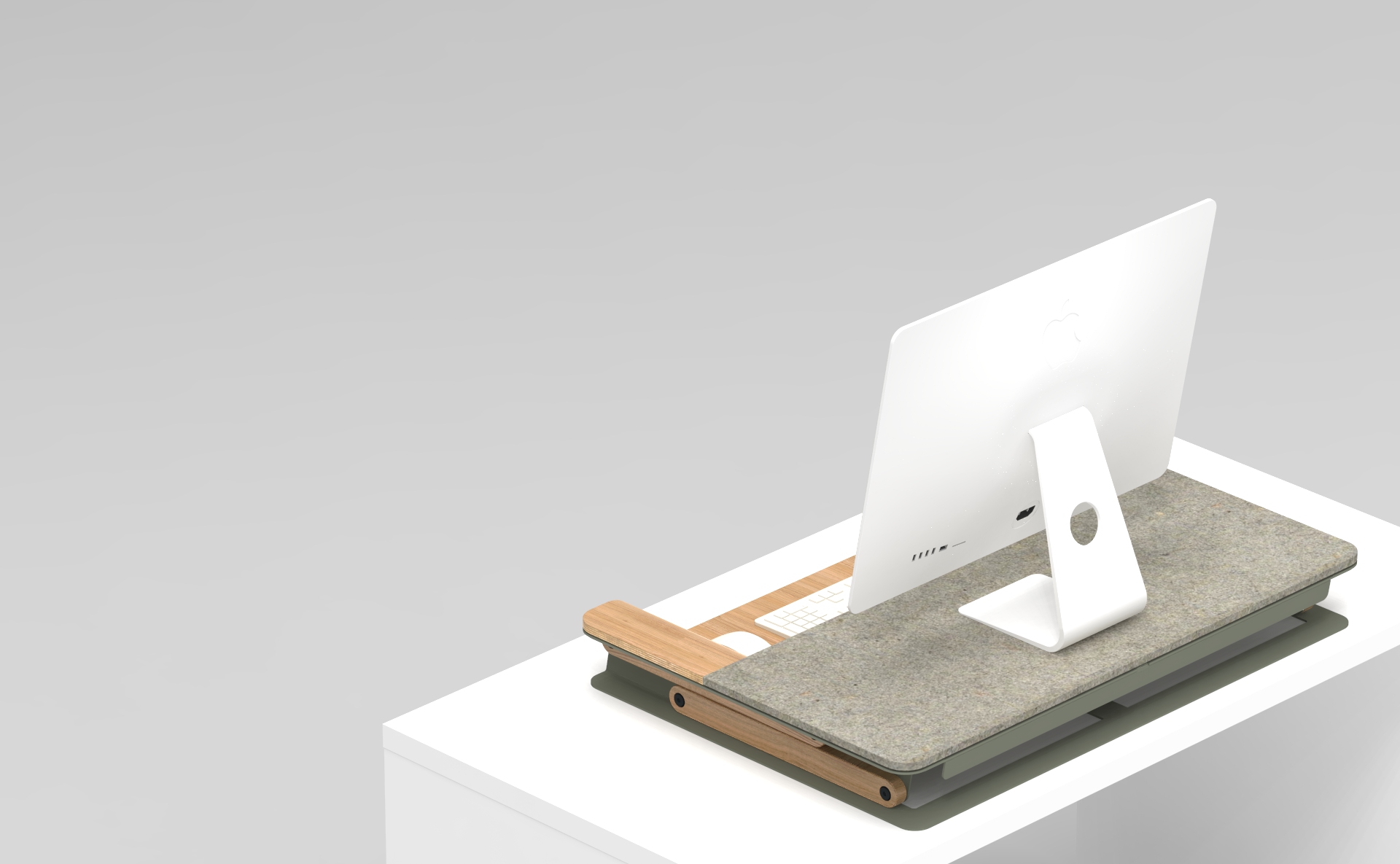

RENDERING

Realistic representations helped aesthetic choices, material choices linked to process of manufacture in addition of presentations and marketing.

prototyping / TESTING

3 prototypes phases were needed to define the shapes and materials along with obtaining the smoothest motion.

The noise reduction was also tested and reduced along the tests.